Reloading Ammo for the AR-15

When I first started reloading, I was afraid to make ammo for anything except bolt-action rifles. I worried that reloaded ammo would cause jams in other types of firearms. As I talked to more experienced reloaders, I learned that reloading ammo for semi-automatic rifles, including the AR-15, isn’t as difficult as I thought. However, there are certain details that I wish I had learned sooner.

Things like which powder and primer to use are covered in reloading manuals. This is basic information that applies to handloading in general. However, there are certain aspects of reloading for an AR-15 that may not apply to reloading for other rifles. Knowing these small details makes the process much easier. Here are some tips for reloading ammo for an AR-15 rifle.

Know Your Barrel’s Twist Rate

One of the first things you need to know before reloading for your AR-15 is your barrel’s twist rate. The twist rate is how many inches a bullet will travel before it completes one full rotation within the rifle’s bore. Different twist rates are designed to stabilize certain ranges of bullet weights.

Bullet stabilization is a very important part of accuracy. Think of someone throwing a football. A good throw will cause the ball to spin as it flies through the air. This spin should continue until another player catches the ball. A bad throw will cause the ball to wobble or tumble as it travels through the air. An unstable bullet will behave in a similar way. Instability wreaks havoc on accuracy, especially at longer distances.

There are a couple of general rules when it comes to twist rates and bullet weights. Barrels with a faster twist rate stabilize heavier bullets better than they do light ones. Conversely, barrels with a slower twist rate stabilize lighter bullets better than they do heavier ones.

The twist rate of your AR-15 will depend on what the rifle was designed for and who made it. Here are the bullet weight ranges for the most common twist rates:

- 1:7 Twist: 55-85 grains

- 1:9 Twist: 45-75 grains

*Note: These are only general guidelines. Be sure to check load data for any bullets that you purchase.

Related: Best Reloading Presses and Kits

Only Use Brass, Boxer Primed, Cases

Make sure that all of your cases are boxer-primed brass. This is true for almost all rifle and pistol reloading but is especially true when reloading for the AR-15. Cheap, steel-cased ammo is all over the place at sporting good stores. If you scavenge brass at your local range, there is a very good chance that you will encounter steel cases there as well.

Steel cases are difficult to reload. While they may be able to go through a set of dies, resizing brass cases is much easier. Even when using case lube, steel cases are much more likely to get stuck. Also, running steel cases through your dies will probably wear them out faster than using brass cases.

Another thing to consider is that most steel-cased ammo uses Berdan primers. These are different from Boxer primers, which are most commonly used when reloading ammo. If you try to place a Boxer primer into a Berdan primed case, you may cause an explosion.

Click here for AR-15/M16 parts & accessories from Brownells.com![]() (affiliate link)

(affiliate link)

You Need to Remove the Primer Crimp

Most .223 and .556 brass cases will have primer crimps. The crimps are meant to prevent the primers from vibrating out of the case as the gun is firing. Unfortunately, they make removing used primers more difficult, and the crimps must be removed before you can push another primer into the case. If you attempt to push a new primer into a case without removing the crimp, you may crush the primer. There is also a chance that it will detonate, which wouldn’t be fun.

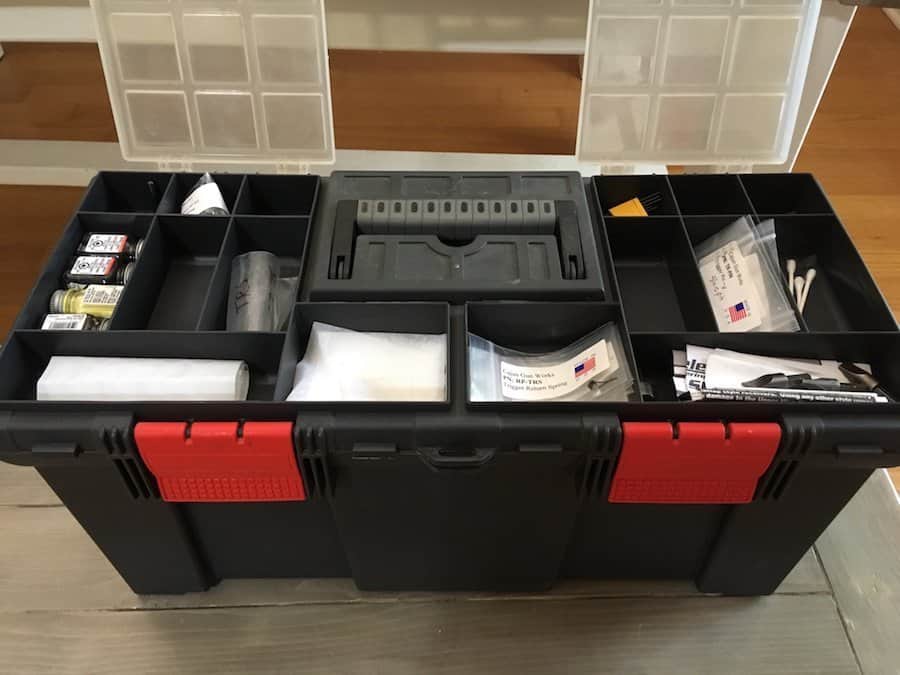

There are a couple of different ways to remove primer crimps. The first way is to use a small cutting tool that will shave the additional metal off of the edge of the primer cup. I have one of these on my case prep center which does a good job. The second way is to use a primer pocket swaging tool. A swaging tool will reshape the primer pocket to eliminate the crimp. These tools are usually mounted on a workbench. Either method will remove the primer crimp and allow you to seat a new primer in the case.

Related: Essential Reloading Equipment: Tools for Handloading

Use the Right Primers

As I started reloading ammo for my AR-15, I started to have problems with pierced primers. The load I was using was well within limits specified in my reloading manuals. I also checked to make sure there wasn’t a problem with the rifle itself. As I researched my problem, I read on forums that many people were having similar issues.

They were blaming their pierced primers on a combination of the rifle using a free-floating firing pin and the primers they were using. An AR-15 firing pin does not have any spring tension on it. Because of this, there is nothing to dampen the impact of the firing pin hitting the primer. This is why if you chamber a round in your AR-15 and then eject it without firing it, you will see a small dent in your primer. This is a normal result of having a free-floating firing pin

At the time, I was using Winchester Small Rifle primers. Many other people experienced pierced primers when using them in reloads for their AR-15. There is a lot of debate as to why it happens, but it is a widely cited problem on several forums. I switched to CCI primers and have not had any problems since. I try to collect my brass after I shoot, and I haven’t seen any pierced primers in years.

If you have a problem with pierced primers, inspect your firing pin and bolt. Sometimes the hot gases that leak out from the hole in the pierced primer can damage those parts. If you see any damage, replace them. Failing to do so will result in more pierced primers and may cause more dangerous problems later.

Full-Length Size Your Cases

When reloading ammo for an AR-15, you need to full-length size your cases. Full-length sizing is a little harder on your brass but is necessary when reloading ammo for semi-automatic rifles like the AR-15. The other method of resizing cases, neck sizing, is good if you reload ammo for bolt-action rifles. It allows the case the retain its fire-formed dimensions, which helps with accuracy.

A full-length resizing die will resize the entire case, not just the neck, to its original dimensions. This allows the case to chamber with less difficulty, reducing feeding problems, and increasing reliability.

Trim Your Cases

After you have sized your cases, you will need to check their length. Be sure to do this after you have resized your cases. The resizing process will correct the width of the case, which will make the case longer than it was before. It is like taking a roll of clay in your hand and squeezing it. As you squeeze the clay, the width decreases, but the length will increase as you add pressure.

You can check case length with a case gauge or calipers. Use a case trimmer to trim any case that is longer than the maximum case length specified in your reloading manual or that sticks out of the case gauge. If you don’t have a case trimmer, set the case aside and save it until you get one.

Using brass cases that are too long can cause a few different problems with your reloads. The biggest potential problem is your ammo may not even chamber in your rifle, making it useless. It can also cause problems with accuracy and when you try to crimp your case neck.

Crimp Bullets, But Only Those With a Cannelure

The act of an AR-15 rifle chambering a round is a violent process. The bolt pushes the round out of the magazine, ramps it up into the chamber and pushes it forward. The bolt then rotates shut. All of this takes place in a fraction of a second. Sometimes during this process, the bullet will get pushed into the case as it is being chambered.

A good way to avoid this is to add a crimp to the top of the case neck. This will press the end of the case neck into the bullet, giving it a tighter hold. You should only do this with bullets that have a cannelure. A cannelure is an indentation that goes around the diameter of a bullet. Your crimp should push the brass into this area of the bullet. Crimping into a bullet without a cannelure could damage the bullet’s jacket.

Check the Cartridge’s Overall Length

The overall length of your completed ammo is extremely important when reloading for any semi-automatic firearm, including the AR-15. Having a correct overall length will help you make sure that your rounds will chamber reliably. Rounds that are too long may not even fit in your magazine. Use the information contained in your reloading manual and calipers to make sure that your first round has an overall length that is within specifications. Doing this on the first round will prevent you from loading a bunch of out-of-spec ammo.

Conclusion

Although I was originally apprehensive about reloading ammo for my AR-15, it is now one of my favorite guns to reload for. I think I have reloaded more .223 rounds than any other caliber. As long as you are aware of the information above and follow your reloading manual, you should have no problem producing accurate and reliable ammo for your AR-15.

If you have never reloaded ammunition before or are just getting started, be sure to check out my other basic reloading articles: